1 How to identify ISO 6162-1 and ISO 6162-2 flange port

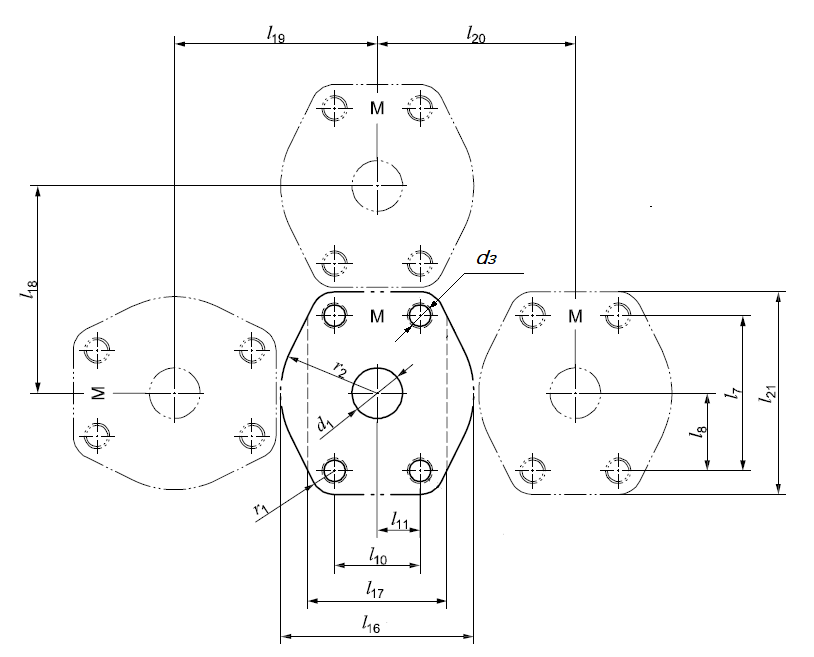

See table 1 and figure 1, compare the key dimensions for identify ISO 6162-1 (SAE J518-1 CODE 61) port or ISO 6162-2 (SAE J518-2 CODE 62) port.

Table 1 Flange port dimensions

|

Flange size |

Flange port dimensions |

||||||||

|

ISO 6162-1 (SAE J518-1 CODE 61) |

ISO 6162-2 (SAE J518-2 CODE 62) |

||||||||

|

Metric |

Dash |

l7 |

l10 |

d3 |

l7 |

l10 |

d3 |

||

|

Metric screw |

Inch screw |

Metric screw |

Inch screw |

||||||

|

13 |

-8 |

38.1 |

17.5 |

M8 |

5/16-18 |

40.5 |

18.2 |

M8 |

5/16-18 |

|

19 |

-12 |

47.6 |

22.2 |

M10 |

3/8-16 |

50.8 |

23.8 |

M10 |

3/8-16 |

|

25 |

-16 |

52.4 |

26.2 |

M10 |

3/8-16 |

57.2 |

27.8 |

M12 |

7/16-14 |

|

32 |

-20 |

58.7 |

30.2 |

M10 |

7/16-14 |

66.7 |

31.8 |

M12 |

1/2-13 |

|

38 |

-24 |

69.9 |

35.7 |

M12 |

1/2-13 |

79.4 |

36.5 |

M16 |

5/8-11 |

|

51 |

-32 |

77.8 |

42.9 |

M12 |

1/2-13 |

96.8 |

44.5 |

M20 |

3/4-10 |

|

64 |

-40 |

88.9 |

50.8 |

M12 |

1/2-13 |

123.8 |

58.7 |

M24 |

- |

|

76 |

-48 |

106 |

61.9 |

M16 |

5/8-11 |

152.4 |

71.4 |

M30 |

- |

|

89 |

-56 |

121 |

69.9 |

M16 |

5/8-11 |

- |

- |

- |

- |

|

102 |

-64 |

130 |

77.8 |

M16 |

5/8-11 |

- |

- |

- |

- |

|

127 |

-80 |

152 |

92.1 |

M16 |

5/8-11 |

- |

- |

- |

- |

Figure 1 Port dimension for flange connections

From table 1, Dash-8 and -12 sizes, it is same screw dimensions and closely l7 and l10 for ISO 6162-1 and ISO 6162-2, so need inspect the l7 and l10 dimensions carefully, and measured with an accuracy of 1 mm or less.

2 How to identify ISO 6162-1 and ISO 6162-2 flange clamp

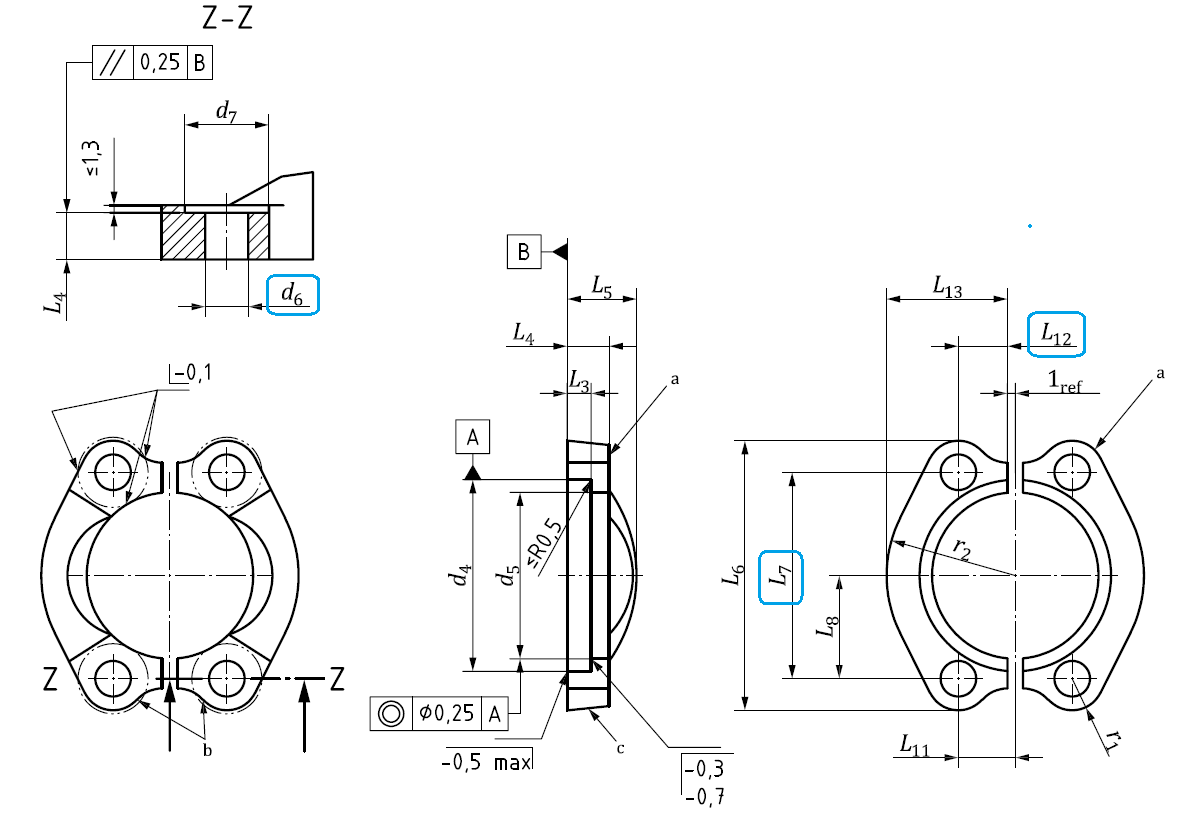

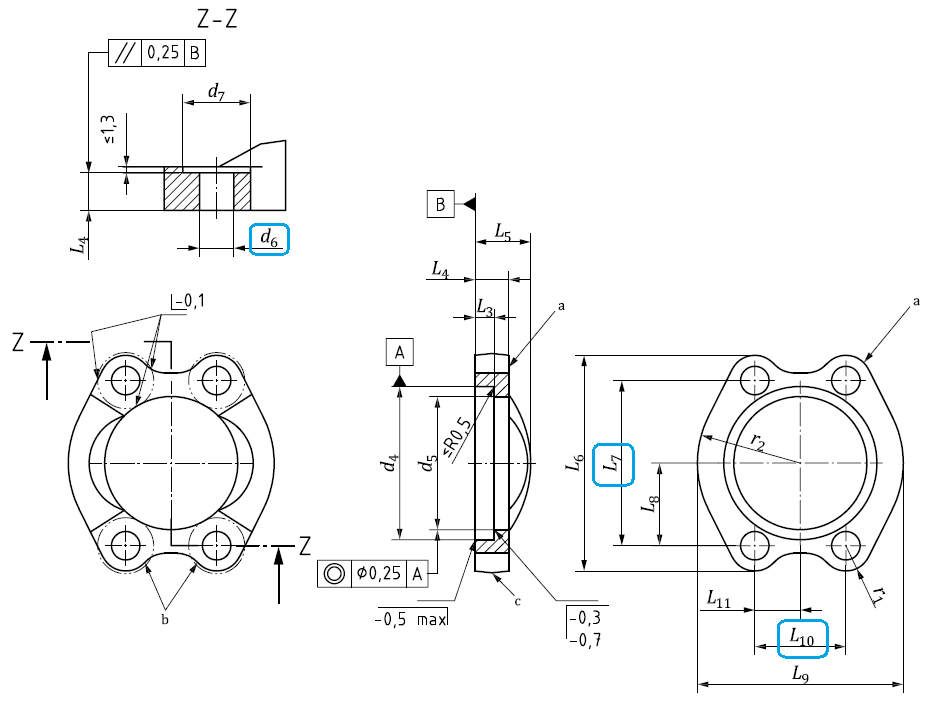

See table 2 and figure 2, figure 3, compare the key dimensions for identify ISO 6162-1 (SAE J518-1 CODE 61) flange clamp or ISO 6162-2 (SAE J518-2 CODE 62) flange clamp.

If it is split flange clamp, inspect and compare l7, l12 and d6 dimensions.

If it is one-piece flange clamp, inspect and compare l7, l10 and d6 dimensions.

Table 2 Flange clamp dimensions

|

Flange size |

Flange clamp dimensions (mm) |

||||||||

|

ISO 6162-1 (SAE J518-1 CODE 61) |

ISO 6162-2 (SAE J518-2 CODE 62) |

||||||||

|

Metric |

Dash |

l7 |

l10 |

l12 |

d6 |

l7 |

l10 |

l12 |

d6 |

|

13 |

-8 |

38.1 |

17.5 |

7.9 |

8.9 |

40.5 |

18.2 |

8.1 |

8.9 |

|

19 |

-12 |

47.6 |

22.2 |

10.2 |

10.6 |

50.8 |

23.8 |

10.9 |

10.6 |

|

25 |

-16 |

52.4 |

26.2 |

12.2 |

10.6 |

57.2 |

27.8 |

13.0 |

13.3 b |

|

32 |

-20 |

58.7 |

30.2 |

14.2 |

10.6 a |

66.7 |

31.8 |

15.0 |

13.3 |

|

38 |

-24 |

69.9 |

35.7 |

17.0 |

13.3 |

79.4 |

36.5 |

17.3 |

16.7 |

|

51 |

-32 |

77.8 |

42.9 |

20.6 |

13.5 |

96.8 |

44.5 |

21.3 |

20.6 |

|

64 |

-40 |

88.9 |

50.8 |

24.4 |

13.5 |

123.8 |

58.7 |

28.4 |

25 |

|

76 |

-48 |

106.4 |

61.9 |

30.0 |

16.7 |

152.4 |

71.4 |

34.7 |

31 |

|

89 |

-56 |

120.7 |

69.9 |

34.0 |

16.7 |

- |

- |

- |

- |

|

102 |

-64 |

130.2 |

77.8 |

37.8 |

16.7 |

- |

- |

- |

- |

|

127 |

-80 |

152.4 |

92.1 |

45.2 |

16.7 |

- |

- |

- |

- |

|

a, 10.6 for metric screw, and 12.0 for inch screw |

|||||||||

Figure 2 Split flange clamp

Figure 3 One-piece flange clamp

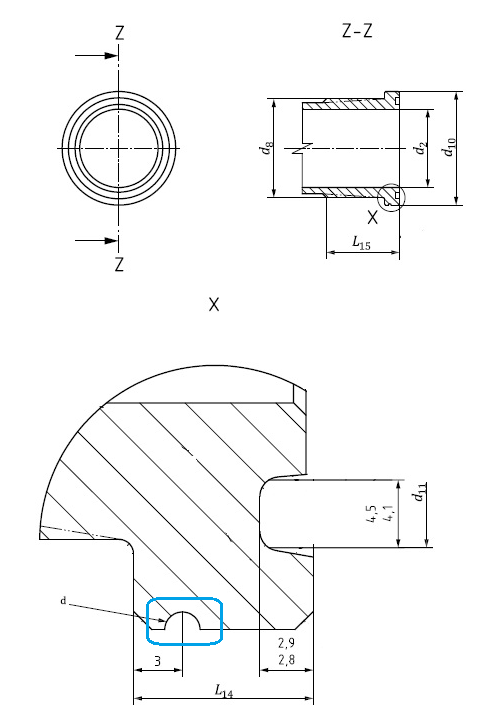

3 How to identify flange head

From table 3 and figure 4, compare the key dimensions for identify ISO 6162-1 (SAE J518-1 CODE 61) flange head or ISO 6162-2 (SAE J518-2 CODE 62) flange head.

And if there is an identification groove located on the circumference of the flange disk, see figure 4 blue marked, it is ISO 6162-2 flange head. (this mark is optional before, so not all of ISO 6162-2 flange heads have this mark)

Table 3 Flange head dimensions

|

Flange size |

Flange head dimensions (mm) |

||||

|

ISO 6162-1 (SAE J518-1 CODE 61) |

ISO 6162-2 (SAE J518-2 CODE 62) |

||||

|

Metric |

Dash |

d10 |

L14 |

d10 |

L14 |

|

13 |

-8 |

30.2 |

6.8 |

31.75 |

7.8 |

|

19 |

-12 |

38.1 |

6.8 |

41.3 |

8.8 |

|

25 |

-16 |

44.45 |

8 |

47.65 |

9.5 |

|

32 |

-20 |

50.8 |

8 |

54 |

10.3 |

|

38 |

-24 |

60.35 |

8 |

63.5 |

12.6 |

|

51 |

-32 |

71.4 |

9.6 |

79.4 |

12.6 |

|

64 |

-40 |

84.1 |

9.6 |

107.7 |

20.5 |

|

76 |

-48 |

101.6 |

9.6 |

131.7 |

26 |

|

89 |

-56 |

114.3 |

11.3 |

- |

- |

|

102 |

-64 |

127 |

11.3 |

- |

- |

|

127 |

-80 |

152.4 |

11.3 |

- |

- |

Figure 4 Flange head

Post time: Jan-20-2022